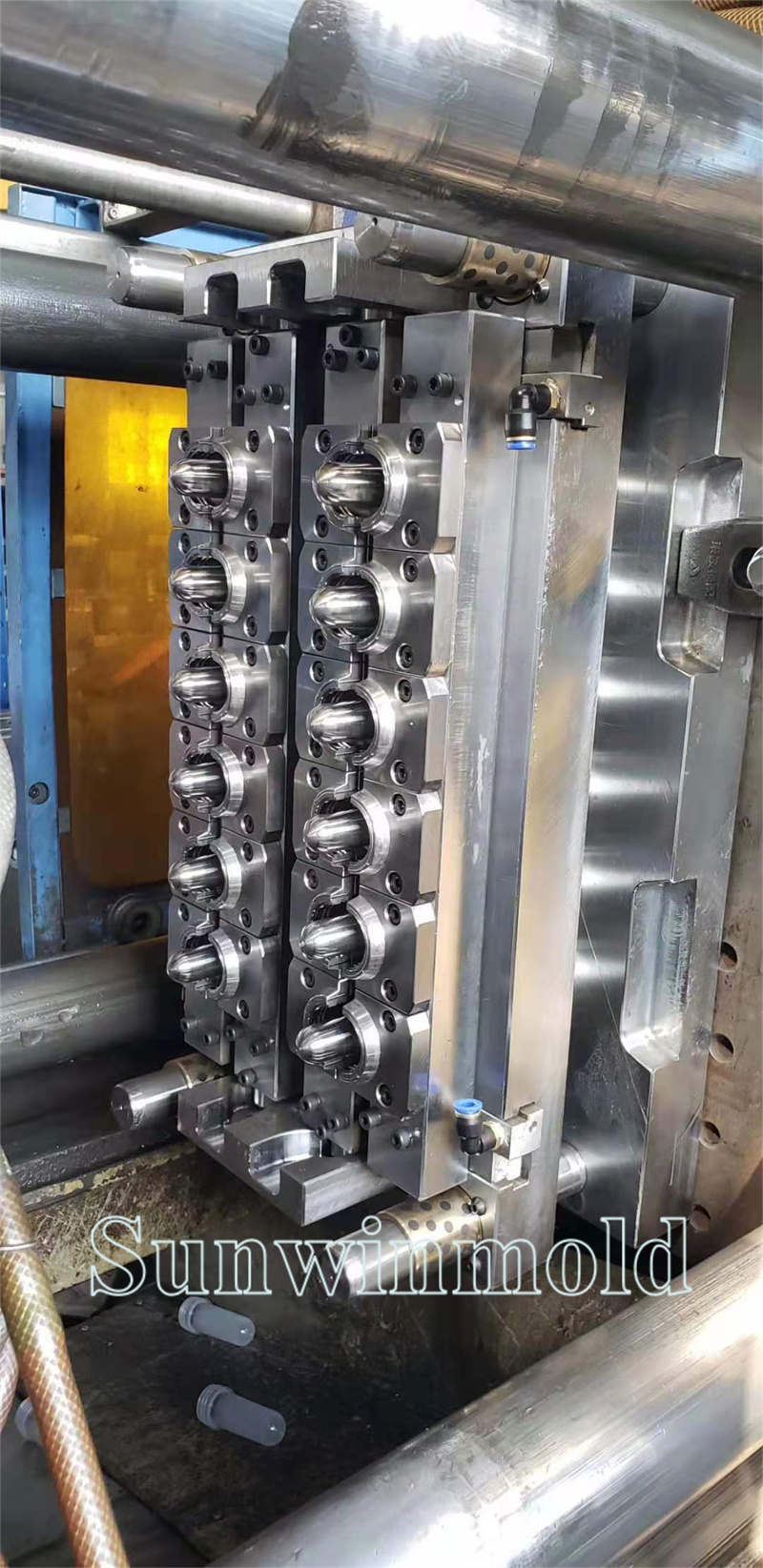

24 Cavity PET Preform Mold

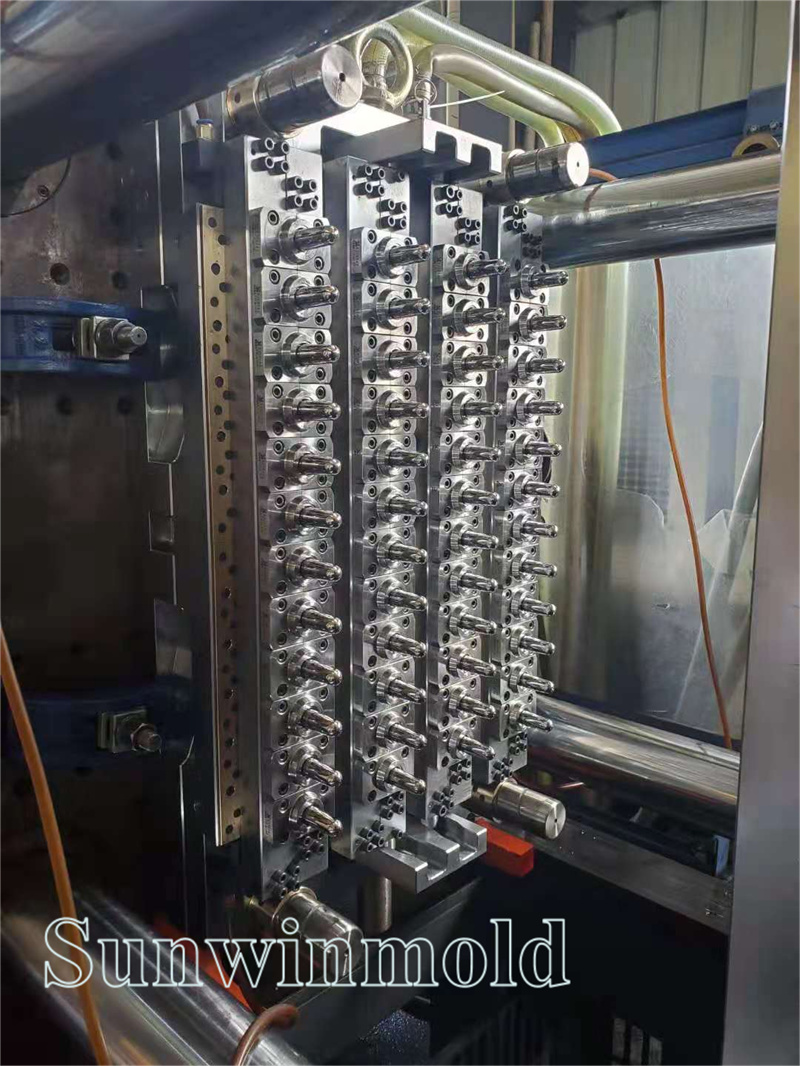

48-Cavity Pin Valve PET Preform Mold

1. Mumhanyi anopisa anotora PID control system, iyo inoratidzirwa nekugadzirisa otomatiki uye mabasa ekudzivirira otomatiki, ayo anogona kurebesa hupenyu hwebasa remagetsi kupisa mudziyo;

-Kupisa kunodzorwa mukati me1 ° C kuti ive nechokwadi chokuti zvinhu zvakasvibirira hazvina kupiswa mumhanyi unopisa, uye chiyero chakapedzwa chechigadzirwa chinogona kusvika kupfuura 99%;

-Iyo nyowani dhizaini inoita kuti mold ive nyore kuchengetedza, iyo thimble chikamu chemhino, iyo yekudziya chikamu, iyo inopisa insulation chikamu, uye thermocouple inogona kutsiviwa nyore nyore pasina kuparadzanisa mold, izvo zvinobatsira kuderedza nguva uye kuchengetedza mari yekuchengetedza. .

2. Kutonhora system

-Iyo spiral cavity inotonhodza mvura chiteshi inoita kuti kutonhora kuite kusimba.

-Iyo inotonhodza mvura chiteshi pane yakarukwa chiteshi uye inotsvedza inosimudzira kutonhora maitiro.

-Yakanyatsogadzirirwa yepakati yekugovera ndiro, mvura inotonhorera inogona kuiswa zvakaenzana mugomba rega rega, uye ese mapreforms anogona kunyatso kutonhodzwa zvakaenzana uye nekukurumidza.

3. Mumhanyi anopisa

-Iyo mumhanyi anopisa ane yakanakisa chiyero kuita inovimbisa kuyerera uye kudzvanywa kwePET kunyungudika mumakomba ese ari yunifomu.

-PET melt channeling inoderedza kugerwa uye IV kurasikirwa uye inobvumira PET kunyunguduka kuyerera zvakaenzana kumakomba ese.

-Kugovera kwakaringana kupisa kunochengeta iyo acetaldehyde (AA) yemukati mumakomba ese akagadzikana.zvinhu

Custom Material 632: Zvirinani pane FS136 ine yepamusoro nickel uye chromium zvirimo.

Kuoma, kuramba ngura, uye kuchena mhedzisiro zviri pachena zvakagadziridzwa.

Iyo mold base yakagadzirwa neHRC 38 ~ 40 simbi isina tsvina kana P20 (pre-yakaomeswa).

2. Stack dhizaini yeSelfLock mhando

Usati wavhara mold, musono wekuparadzanisa unovharirwa panzvimbo nemhete yekukiya kuti uderedze kupfekedzwa kwemutsara wepakati padivi pegomba uye nechepakati, nekudaro uchiwedzera hupenyu husina burr hwemutsara wekuparadzanisa.

Nhanganyaya yeMold Manufacturing

| Type | Urefu(mm) | Upamhi(mm) | Hukobvu(mm) | Huremu(kg) |

| 6 Cavity | 650 | 270 | 490 | 600 |

| 8 Cavity | 480 | 360 | 490 | 595 |

| 12 Cavity | 610 | 360 | 490 | 755 |

| 16 Cavity | 740 | 360 | 510 | 960 |

| em magan vadivelu comedy Cavity | 790 | 500 | 510 | 1415 |

| 32 Cavity | 800 | 580 | 510 | 1600 |

| 48 Cavity | 1120 | 600 | 560 | 2640 |

| 64 Cavity | 1380 | 600 | 610 | 3545 |

| 72 Cavity | 1170 | 800 | 610 | 4010 |

| 96 Cavity | 1230 | 960 | 610 | 5050 |

Iyo data iri pamusoro yakavakirwa pane 16g preform ine PCO mutsipa.

48-Cavity Mhepo Yakavharwa PET Preform Mold

1. Nyanzvi uye ruzivo rwehunyanzvi mune preform mold cavities kubva pa1 kusvika ku96 cavities.

2. Iyo preform mold inoshandisa CAD software kugadzira iyo preform chimiro maererano nebhodhoro kuti ive nechokwadi chekuumba mhando yebhodhoro.

3. Iyo tambo yekuvhura zvinhu ye preform mold inogadzirwa kubva kunze kwenyika nitrided simbi, inogadzirwa maererano nemitemo yenyika, nekuoma kwakanyanya, shinda imwe neimwe inofefetera, uye ine hupenyu hurefu hwebasa pasina deformation.

4. Preform mold core uye mhango inogadzirwa nesimbi isingadziviriri, iyo inogara yakasimba.

5. Iyo preform mold inotora dhizaini yepamberi inopisa mumhanyi, kuitira kuti mhango yega yega inogona kuve yakazvimiririra tembiricha inodzorwa, inopisa, uye tembiricha yakafanana.

6. Cheka-yemahara gedhi preform mold, kuchengetedza basa uye mbishi zvinhu.

7. Kupisa kwemhepo inopisa inomhanya inodzorwa zvakasiyana.(Kugadzirisa dambudziko rekuchena uye kudhirowa waya pazasi panguva yekugadzira).

8. Tsono-vharuvhu self-locking preform mold: imwe neimwe musimboti, mhango, yakazvimirira kaviri-kuzvivharira, inogadziriswa eccentricity, kuderedza eccentricity, simbisa chigadzirwa concentricity, high precision.Iyo mold ine hupenyu hurefu hwebasa.

9. Kutsigira sampuli uye kudhirowa kugadzirisa, kupa chigadzirwa chitsva chekugadzirwa, imwe-stop service yekugadzira jekiseni molding processing!

48-Cavity Mhepo Yakavharwa PET Preform Mold

1. Mold zvinhu:

1. Isu tinonyanya kugadzira zviumbwa zvetsono valves, izvo zvisingadi kucheka kwemaoko.

2. Kushandiswa kwepamusoro hot runner system kunovimbisa kuti kukosha kweAA kwechigadzirwa kwakaderera.

3. Zvinonzwisisika kutonhora kwemvura dhizaini dhizaini inosimbisa kutonhora kweiyo mold uye zvinobudirira inopfupisa jekiseni rekuumba kutenderera.

2. Kusarudzwa kwezvinhu:

1. Zvikamu zvikuru zvekuumbwa zvinogadzirwa kubva kunze kwenyika S136 zvinhu (Sweden-Sabak).

2. Iyo mold base material inotora kunze kwenyika P20 zvinhu uye electroplating kurapwa, iyo inovandudza kusimba kwekuora kwechiumbwa uye inowedzera hupenyu hwebasa remuumbi.

3. Kupisa kwekupisa kwezvikamu kunogadziriswa muchoto chevacuum chinotengeswa kubva kuGermany, uye kuoma kwezvikamu kunovimbiswa kuva paHRC45 ° -48 °.

4. Yepamberi yekugadzirisa michina:

Iyo kambani yakaunza huwandu hwemichina yemidziyo inotengeswa kubva kuUnited States neJapan, senge machining centers, CNC lathes, EDM, nezvimwewo, kuti ive nechokwadi chekuti machining akarurama ezvikamu uye kuita kuti zvikamu zvive nekuchinjika kwakanaka., kukanganisa kwehuremu kwakaderera kupfuura 0.3g, 2-5 molds inogona kugadzirwa muminiti imwe, uye hupenyu hwebasa hunogona kusvika mamiriyoni maviri mold times.

em magan vadivelu comedy Cavity Preform Mold

Iyo nyowani preform mold chimiro yakazvimiririra yakatsvagirwa uye yakagadziridzwa inogona kubvisa zvachose yakawanda yekuipa kweakapfuura mold, uye inokwanisa kuwana yakakwira-chaiyo concentricity uye hupenyu hurefu hwe mold, uye inogona kuita yakajairwa yezvikamu zvakasiyana zve mold uye kugadzirwa kwakawanda.Zviumbwa zvedu zvinovimbisa kuti musiyano wemadziro echubhu isina chinhu isingasviki 0.05mm, uye uremu kukanganisa kwakaderera pane 0.3g.2-5 molds inogona kugadzirwa muminiti imwe, uye hupenyu hwebasa hunogona kusvika mamiriyoni maviri mold nguva.Iyo mold ine huwandu hwe96 cavities.

12 Cavity PET Preform Mold

1. Inotengeswa kunze S136 simbi mhango, musimboti, uye threaded mutsipa anoshandiswa, uye kupisa kurapwa kuoma kunogona kusvika HRC 48-50;ese maformworks anorapwa kupisa nekuoma kweHRC 30-35.

2. Advanced mold design tekinoroji: Imwe neimwe mhango inozvivharira yega, ichishandisa yakakwirira-chaiyo yeJapan SYATEM.Kuve nechokwadi chekuderera kwemuviri wehuwandu uye kunyatsojeka kwechigadzirwa.Imwe neimwe inofa ine spare insert yezvikamu zvinogara zvinochinjika.Kuti tivandudze uye tibudirire kugadzirwa kwepamusoro, tinogara tichigadzira yakanakisa kutonhora sisitimu, uye tinokwanisa kuenzanisa muchina wekutonhodza wemold yega yega.

3. Yepamberi uye chaiyo vharafu inopisa mumhanyi uye tembiricha controller inovimbisa kuvimbika kwekugadzirwa uye yakakwirira mwenje transmittance uye kupenya kwechigadzirwa.

4. Mushonga unotsvedza wakagadzirwa nemhangura, muviri webhodhoro unosangana nehuwandu hwekuchengetedzwa kwezvokudya, uye hupenyu hwehuputi hunovimbiswa kuva hunopfuura mamiriyoni matatu nguva.1.Mold zvinhu:

1. Isu tinonyanya kugadzira zviumbwa zvetsono valves, izvo zvisingadi kucheka kwemaoko.

2. Kushandiswa kwepamusoro hot runner system kunovimbisa kuti kukosha kweAA kwechigadzirwa kwakaderera.

3. Zvinonzwisisika kutonhora kwemvura dhizaini dhizaini inosimbisa kutonhora kweiyo mold uye zvinobudirira inopfupisa jekiseni rekuumba kutenderera.